- Report: #524801

Complaint Review: Print Harmony - Clearwater Florida

Print Harmony Beware!!! Refusal to reprint job which arrived glued together at client's office... Basically told that they were not going to stand behind their product. Clearwater, Florida

*Author of original report: PRINT HARMONY OF CLEARWATER REFUSES TO STAND BY THEIR PRODUCTS!!!

*UPDATE Employee: Understanding offset printing and how to create files

*Author of original report: Response is a Complete Fabrication

*Consumer Comment: re:

*Consumer Comment: wow

*Consumer Comment: Pre-Press Catches...

*Consumer Comment: Ripped Me Off Too

*Consumer Suggestion: solution

*General Comment: print harmony

*Consumer Comment: Pre-Press Issues and Printing

Report Attachments

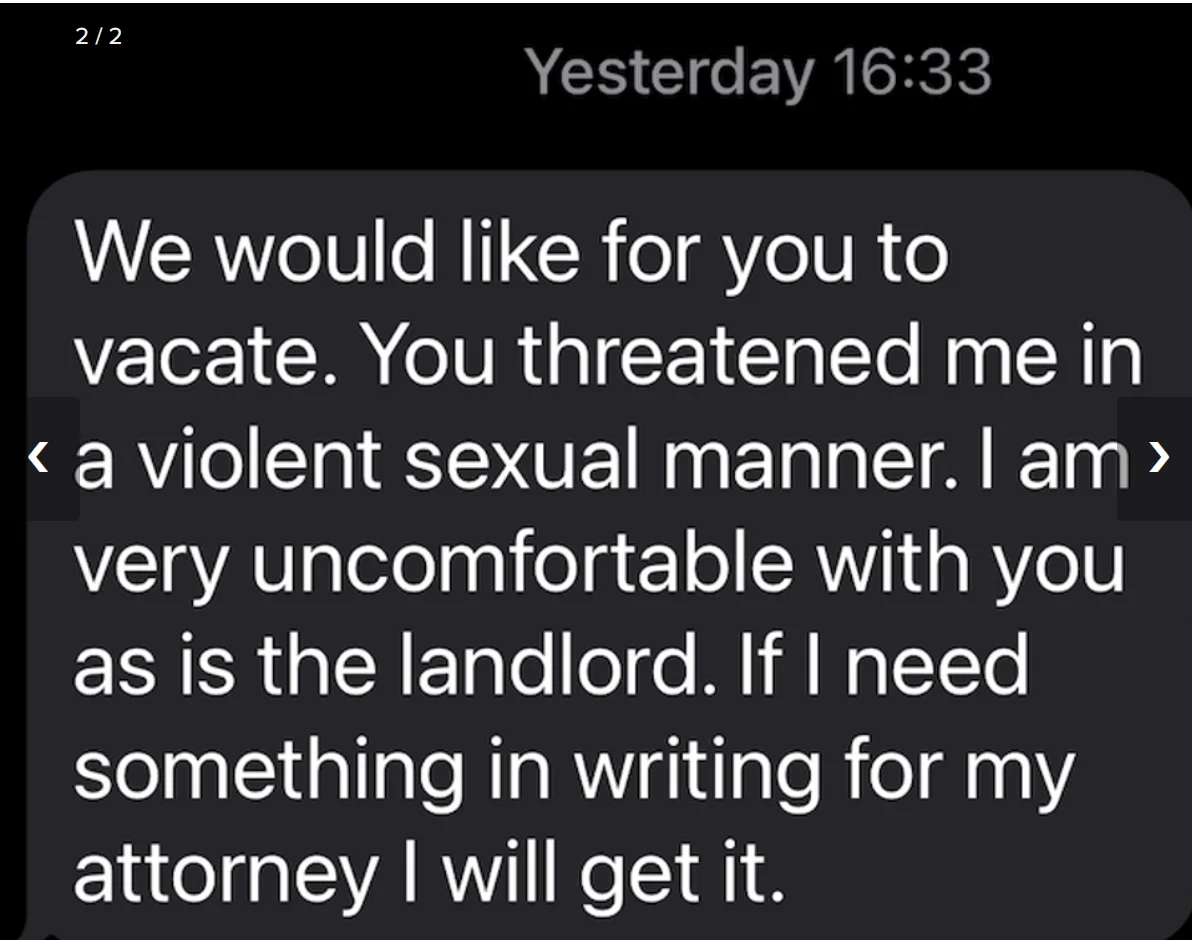

When the flyers arrived, they were glued together in one corner because they were packaged before they were dry. Contacted Customer Service and they said they would contact us the next day. We were contacted the next day and told that they were not going to reprint the job. The customer service Rep I spoke to "Chloe" basically told me "the job would NEVER dry"... and they "usually catch problems in pre-press but they missed this one."

Basically, they blamed us for the problem because of the choice of the color black we used. We paid for full-color flyers. There is nothing in the terms and conditions or artwork specifications on their website that makes any reference to any issues or possibility of issues from using CMYK 100% Black, which is the default black in every graphic design program sold today. Photoshop, Corel, Illustrator ALL use this as the default black.

Yet we are told that using this black is the reason our items were shipped wet. I have been in business 7 years (we have had approximately 10 bad printer jobs in that time) and we have never had a printer tell us to eat a job that arrived damaged or printed poorly. When I spoke to the Rep myself, after my employee was unable to get any satisfaction, I was basically told that it was an unwritten rule that you don't use this black over that black... If this is an issue, my response to the customer service Rep Chloe that you would think it would become a "written" rule to protect other designers in the future.

This printer has an extensive Terms and Conditions page that basically protects them against any and all litigation no matter what the cause or who is at fault even if it is their fault entirely. I have also always been treated with absolute respect by every other printer I have done work with. And in the 10 or so instances in 10 years where the product arrived defective, the other printers I use have ALWAYS done the right thing, stood by their product and tried to find a fair solution.

We are not asking for a refund... They can have the problem items back. We simply wanted a reprint that wasn't stuck together. They did not so much as even offer to reprint them at their cost, which I would be willing to pay just to make my client happy. They were completely unwilling to do anything at all to keep us a happy client. I do over $600K a year in printing out of my office and they will never get another dime out of me. They basically want me to print the job again at their full retail mark up! As is is, typically printers make 2x their cost or more. So a $1000 print job nets $500 profit for the printer. So even if they do re-print the job, they don't "lose" money.

I have never dealt with a company that has been so unreasonable and so unwilling to make things right when the problem is on their end. I'm sure they will respond to this and say it was our fault because of what they say is our using the wrong 'black'. But the point is that they do not make any reference on their website to any issues regarding the use of any colors or anything else that could defend their position on this job. If there had been such a warning, then I would have simply taken the loss. But, considering how comprehensive their Terms and Conditions and Specs are it seems odd that they have no reference to something that is such a "common issue".

So, Buyer Beware and make sure you read Terms and Conditions on websites before you order anything. If their Conditions are 90% legal speak protecting them from providing you refunds for any reason if the work they provide is not satisfactory, then you should probably be careful. (READ BELOW)

Workmanship Guarantee

Because of the nature of offset printing, on rare occasions the following may occur: variation in color, offset (smudges), cutting variations, marking, picking, etc. Because of cutting it is possible that all printed materials may be trimmed by 1/16th of an inch undersized on all sides (please address all art appropriately). Customer acknowledges that they are receiving printing at a substantial price discount and expedited delivery times and thus said printing will not be held to the same standard as traditional offset lithography nor generally accepted printing standards. While every effort will be made to satisfy our customer's needs, requests for reprints or credits based on quality issues will not be recognized.

So, basically, they are stating that if it arrives wrong, too bad... Must be nice to not have any quality standard to adhere to. I wish I could get away with this!

10 Updates & Rebuttals

Vann

Duluth,Georgia,

Pre-Press Issues and Printing

#2Consumer Comment

Tue, May 13, 2014

I have been working with Print Harmony for about two years now on a wide range of print projects.

I am also a graphic designer, who apprenticed early in my career with two printing companies for a total of 9 years and I have worked with dozens of printing companies in the printing of four color marketing materials for over 30 years.

Rich Black

First off, I agree with several who have commented that printing 100% of each of four colors to achieve a "rich black" will put a LOT of extra ink on the paper and will create a much longer drying time than usual, and it should be avoided if at all possible.

I have used "rich black" printing on a couple of projects back in the early 1990s, which was before digital files were used to image right to printing plates (as it is done now), and my printer and I discussed the longer drying time and we waited to cut until after the ink was completely dried after several days.

The problem today is that many print projects are "ganged" together on a single press run, so if one file uses rich black, waiting several days for the printed sheets to dry means several projects are held up from cutting and shipping.

Pre-press file checking

Most printers use pre-press software which can spot many common problems with files where the file creator has introduced a potential printing problem. Software cannot be relied on to catch every single pre-press problem.

I had this exact issue come up with a postcard design a while back with a another printer. Fortunately for me it was caught in prepress after I submitted the file, I was notified, and I submitted an altered file without the rich black so there was no problem.

Customer & Printer Responsibilities

As a designer, and the one submitting files to a printer, I understand that I cannot rely 100% for the printer to spot a pre-press mistake I have made, and I fully expect to have to pay for a reprint of a job if I have submitted a file where I have not set up my files correctly or where I changed trap settings, or submitted RGB tiffs instead of CMYK, etc.

Back in the 1980s and even into the 1990s the majority of pre-press work was still done by the printer, either creating the fies or working from files submitted by customers and it was quite common for printers to "fix" file problems before running film then making plates.

Today, most printers are receiving a PDF X1a or similar file which goes right into the printer's pre-press system for pre-flight which is all handled by software.

The digital pre-press and other efficiencies which give us terrific printing prices and the ability to gang print means there is also a greater reliance on the designer getting the printing files right the first time, and catching potential problems via software.

Print Harmony Rocks

What I have learned over the years is that it's best to build a relationship with a printer and to fully understand all aspects of pre-press files and to develop a methodology so there are no surprises. Printers who you work with on an ongoing basis value this and I have found many printers will go out of their way to work with customers, but they are just not in a position to reprint at their cost every job where the customer is at fault.

Print Harmony has been great to work with. Their customer service is outstanding and any questions I have about a printing job or pre-press files are always answered to my satisfaction. Every print job I have received is spot on.

Sour Grapes

In my opinion, the customer who is unhappy simply does not want to admit they are in fact part of the problem. Based on the customer's reference to having other "bad" printing jobs, it seems like they are not novices and should accept some responsibility for the problem they created.

loopyg

Iowa,print harmony

#3General Comment

Wed, January 15, 2014

I've been in the printing industry over 30 years (on the production side) and after looking at the attached photo from GM, I would have to agree with you. Even though creating a 400% black is definitely a NO-NO in offset printing, from what I see in the photo isn't from too much ink, but from cutting the piece before it was dry.

The sticking together of the sheets that I see is from the pressure of the cutter clamp that holds the stack of sheets together before the knife cuts the stack. If the ink was dry before cutting it, this wouldn't have happened. And yes, 400% ink coverage will dry.....just not as fast as you'd like.

I have a feeling that in order to meet a deadline, it was rushed through the shop and this is what you get.

I suppose you could put part of the blame on whoever designed the piece (using 400% black), but I think most of the blame is on the printer for not allowing enough time for the ink to dry before cutting it, and blame on the cutter operator for not catching it, and on down the line because I'd put money on it that it looked like this before it even left the shop. Typical of hang and bang shops these days. Get it in and out as fast as possible regardless of quality. With that....you get what you pay for.

Whatever conversation you had with print harmony after the fact is a matter of he said, she said at this point, but I still put most of the blame on the printer.

Laura

tampa,Florida,

solution

#4Consumer Suggestion

Fri, January 03, 2014

Printing professionals used to k n o w what they were doing and used to do what ever it takes to produce a quality product. In this case the printer claimed that they knew what caused the problem and yet they didn't take action to prevent the problem. Prepress communication should have been a priority. If not make adjustments in the plan for compatable ink then the possibility of slip sheeting charges should have been discussed.

GAW

Fort Myers,Florida,

Ripped Me Off Too

#5Consumer Comment

Wed, April 17, 2013

To the guy who wrote this complaint. I wish I could speak to you. I'm going to file a class action act against print harmony. They basically did the same thing to me. Except they never printed the job.. NO No.. They had me upload the files, pay for the job and then told me they could not print the order, rendering me a credit. No refund! I was pissed and fought it. Now that the dispute is over and based on their terms they were awarded the win. Now! I get a call from them saying my credit is available to use and they marked up all my costs by 150 - 200% rendering my hard earned $253.53 credit useless.

Should you read this. Please email me at [email protected]

Tampa Designer

Florida,United States of America

Pre-Press Catches...

#6Consumer Comment

Tue, January 29, 2013

I have been a customer of Print Harmony for over 4 years now. I have only had one issue with a job that came from them and they rectified the problem immediately and to my satisfaction.

The job of Pre-Press (for those of you who DON'T know) is to prep the files for plate production, not fix mistakes that designers have made. Print Harmony is a wholesaler, so they are already going on the presumption that their customer's files are ready for printing and do not need any further tweaking, color correction or other corrections. If you need someone to review your files before printing, go to a different printer.

Print Harmony is inexpensive for us designers (and resellers) and makes it more affordable because they've taken out all those steps that aren't needed like the general public needs. And I seriously doubt that they wouldn't have taken care of their customer with offering some sort of discount, even if it was the customer's fault in the file setup. No one in this economy would just simply say "Sorry Charlie. It was your screwup - you pay twice" and not expect some sort of reaction.

I think the original author of this posting needs to get a refresher class on design, or use a printer that will catch all of their mistakes for them.

jg

Williamsport,United States of America

wow

#7Consumer Comment

Tue, January 17, 2012

found this article when i was looking for reviews. i placed an order and it's been two weeks and its not even shipped yet! besides the fact... if the document wasn't set up right isn't it the companys prepress departments job to fix it. if in fact the document was set up with 400% black the prepress department would have noticed and should have seen a problem and made arrangements to change it. isn't the the number one job of prepress... making sure the job is set up correctly for print! Duh! thats how i learned it and what i did at a previous job. i know every workplace is different but seriously? seems dumb they didn't bother to fix it.

John

Louisville,Kentucky,

U.S.A.

re:

#8Consumer Comment

Mon, December 07, 2009

I am a graphic designer and do not know either of these parties. It appears that the printer is correct. Printing @ 100% for each of the CMYK colors is incorrect and the resulting saturation of ink will cause problems like sticking.

Mobile home retiree

Crystal River,Florida,

U.S.A.

Response is a Complete Fabrication

#9Author of original report

Mon, December 07, 2009

Just for the record, we offered to return the job to the printer and asked for a reprint at their cost. They never offered to do anything and I have the recordings of the conversations with "Chloe". So I welcome the "G.M." who responded to my report to call me and listen to the conversations so they can personally see that this Agent never offered anything. Too bad that the respondent never asked us our side of this dispute or contacted us personally. Because things would have gone differently.

And lastly, when I was unable to get anywhere with Chloe, I informed her that I would be contacting the BBB and ripoffreport.com and she told me to have at it. ANY company that truly cared about their clients, would NEVER encourage them to file a complaint.

Fact of the matter is that they never offered anything to rectify the situation.

PLUS: There are other complaints regarding this company on this website. Do a search for "printharmony" with no spaces. You'll see 2 other resellers making the same claim I have. That when there is a problem, they do nothing to make it right... Guess they are lying too.

General Manager

Clearwater,Florida,

United States of America

Understanding offset printing and how to create files

#10UPDATE Employee

Fri, December 04, 2009

First and foremost I'd like to thank our loyal resellers say that we make every effort to fully satisfy all of our over 10,000 print resellers. All of our customers are "trade clients" as we only print for resellers of printing such as other other printers, graphics designers, etc.

Mobile home retiree

Crystal River,Florida,

U.S.A.

PRINT HARMONY OF CLEARWATER REFUSES TO STAND BY THEIR PRODUCTS!!!

#11Author of original report

Wed, November 18, 2009

WARNING!!! Recently ordered full-color flyers from Print Harmony of Clearwater Florida. The order was drop-shipped to the client for a time-sensitive insert into a publication. When the flyers arrived, they were glued together in one corner because they were packaged before they were dry. Contacted Customer Service and they said they would contact us the next day. We were contacted the next day and told that they were not going to reprint the job. The customer service Rep I spoke to "Chloe" basically told me "the job would NEVER dry"... and they "usually catch problems in pre-press but they missed this one." Basically, they blamed us for the problem because of the choice of the color black we used. We paid for full-color flyers. There is nothing in the terms and conditions or artwork specifications on their website that makes any reference to any issues or possibility of issues from using CMYK 100% Black, which is the default black in every graphic design program sold today. Photoshop, Corel, Illustrator ALL use this as the default black. Yet we are told that using this black is the reason our items were shipped wet. I have been in business 7 years (we have had approximately 10 bad printer jobs in that time) and we have never had a printer tell us to eat a job that arrived damaged or printed poorly. When I spoke to the Rep myself, after my employee was unable to get any satisfaction, I was basically told that it was an unwritten rule that you don't use this black over that black... If this is an issue, my response to the customer service Rep Chloe that you would think it would become a "written" rule to protect other designers in the future. This printer has an extensive Terms and Conditions page that basically protects them against any and all litigation no matter what the cause or who is at fault even if it is their fault entirely. I have also always been treated with absolute respect by every other printer I have done work with. And in the 10 or so instances in 10 years where the product arrived defective, the other printers I use have ALWAYS done the right thing, stood by their product and tried to find a fair solution.

We are not asking for a refund... They can have the problem items back. We simply wanted a reprint that wasn't stuck together. They did not so much as even offer to reprint them at their cost, which I would be willing to pay just to make my client happy. They were completely unwilling to do anything at all to keep us a happy client. I do over $600K a year in printing out of my office and they will never get another dime out of me. They basically want me to print the job again at their full retail mark up! As is is, typically printers make 2x their cost or more. So a $1000 print job nets $500 profit for the printer. So even if they do re-print the job, they don't "lose" money. I have never dealt with a company that has been so unreasonable and so unwilling to make things right when the problem is on their end. I'm sure they will respond to this and say it was our fault because of what they say is our using the wrong 'black'. But the point is that they do not make any reference on their website to any issues regarding the use of any colors or anything else that could defend their position on this job. If there had been such a warning, then I would have simply taken the loss. But, considering how comprehensive their Terms and Conditions and Specs are it seems odd that they have no reference to something that is such a "common issue". So, Buyer Beware and make sure you read Terms and Conditions on websites before you order anything. If their Conditions are 90% legal speak protecting them from providing you refunds for any reason if the work they provide is not satisfactory, then you should probably be careful. (READ BELOW) Workmanship Guarantee Because of the nature of offset printing, on rare occasions the following may occur: variation in color, offset (smudges), cutting variations, marking, picking, etc. Because of cutting it is possible that all printed materials may be trimmed by 1/16th of an inch undersized on all sides (please address all art appropriately). Customer acknowledges that they are receiving printing at a substantial price discount and expedited delivery times and thus said printing will not be held to the same standard as traditional offset lithography nor generally accepted printing standards. While every effort will be made to satisfy our customer's needs, requests for reprints or credits based on quality issues will not be recognized . So, basically, they are stating that if it arrives wrong, too bad... Must be nice to not have any quality standard to adhere to. I wish I could get away with this!

Photo shows the flyers stuck together and the damage after we separate...

Report Attachments